Project BIOFLEXPV

Excerpt

Biobased encapsulation materials for flexible photovoltaic modules

Sylvain Chambon, Research fellow, CNRS

ANR reference : 22-PETA-0013

Whatever the photovoltaic (PV) sector, encapsulation materials represent a major challenge. The BioFlexPV project aims to develop new, efficient encapsulation materials based on bio-based materials, thereby reducing the PV industry’s dependence on non-renewable resources and, consequently, its environmental impact. By combining biomass-derived polymers and dense inorganic layers from abundant resources, we aim to manufacture encapsulation films with high gas barrier properties. These new encapsulation materials will be integrated into different types of flexible PV modules, and their lifetime will be studied and analyzed in detail.

By combining this approach with life cycle analysis, the BioFlexPV project aims to develop low environmental impact encapsulation strategies that can be applied to different families of flexible PV modules.

Keywords: Encapsulation, biosourced, photovoltaic, flexible, module

Tasks

Our researches

Polymer synthesis for barrier film and sealant

These polymers will be synthesized from bio-based materials such as cellulose or lignin. They will then be filled with inorganic compounds such as nanoclay. Functional groups will be assigned to the materials to increase their solubility in non-toxic solvents such as alcohols.

Development and optimization of organic/inorganic multilayers

The inorganic part will be composed of materials from abundant resources, either inorganic oxides or inorganic-organic hybrids deposited by ALD (Atomic Layer Deposition), or organosilica-based materials deposited by sol-gel developed within the project. ALD-type deposition techniques will be used, as they are now increasingly implemented at industrial level.

Encapsulating

Various flexible photovoltaic modules will be encapsulated using biosourced materials by low-temperature lamination (with the exception of aluminum).

Recycling and LCA

Studies will be carried out on the recycling and life-cycle analysis of encapsulation materials, packaging materials and processes.

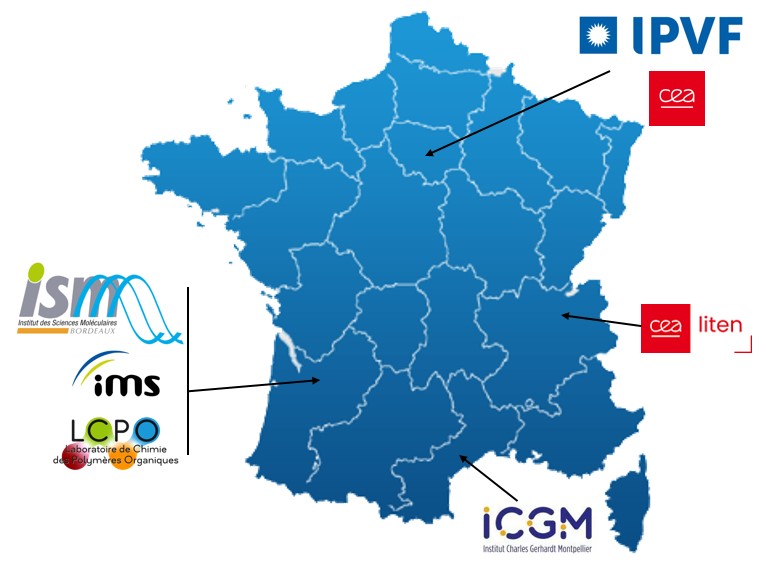

Consortium

The consortium includes 2 laboratories from higher education and research establishments, 3 CNRS mixed units and 2 CEA laboratories.

This project aims to develop a technology that meets a number of prerequisites. The barrier film and sealant polymers will be synthesized from bio-based materials such as cellulose or lignin for the barrier film, and isocyanate-free polyurethane (produced from bio-based building blocks). They will then be filled with an inorganic compound such as nanoclay. The inorganic part will be composed of materials from abundant resources, either inorganic oxides or inorganic-organic hybrids deposited by ALD, or organosilica-based materials deposited by sol-gel. Functional groups will be assigned to materials to increase their solubility in non-toxic solvents such as alcohols. Life-cycle analysis of encapsulation materials and overall processes will be studied by a partner as part of a specific cross-disciplinary working group. The resulting module will be encapsulated by lamination at room temperature.

No news

More projects